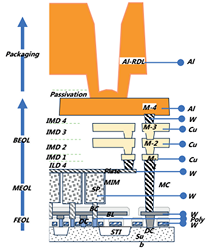

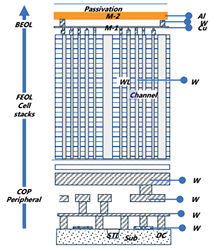

(3D-NAND,DRAM)

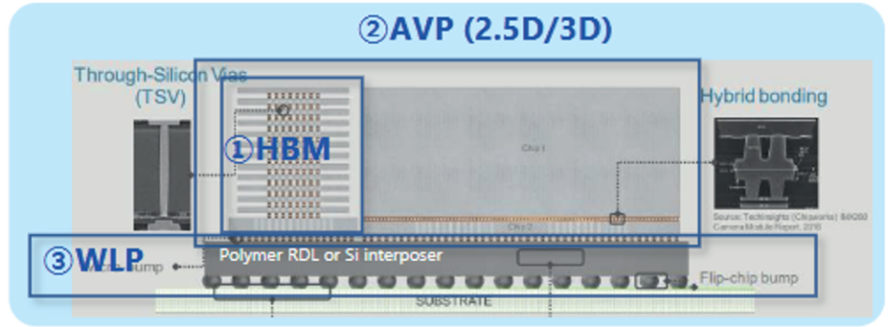

Packaging

WLP

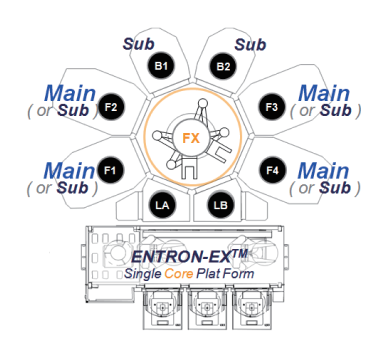

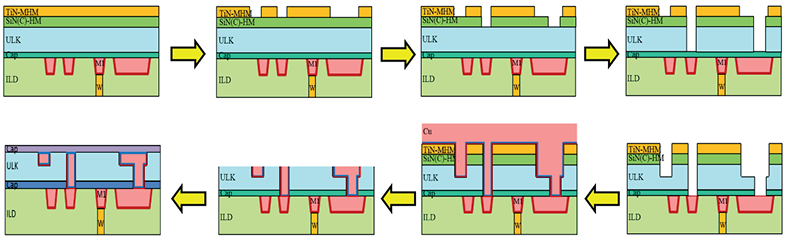

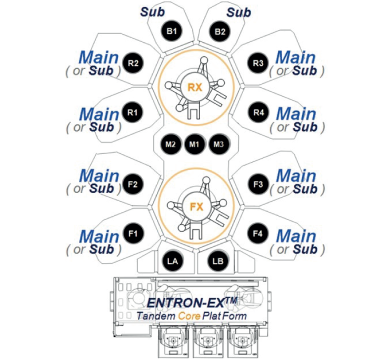

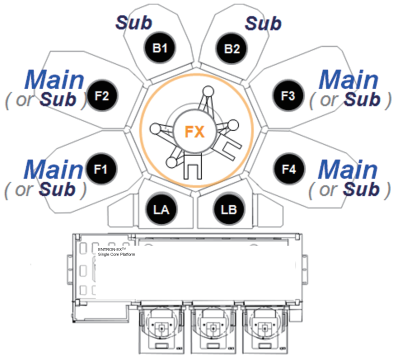

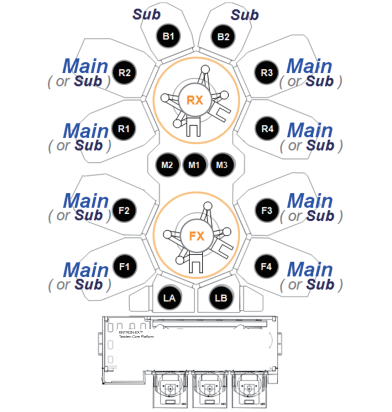

ENTRON™ EX300

RISE™ 300

ENTRON™ SeriesDelivery Record > 500

Main Process Module x 4 + Sub Process Module x 2 + Load Lock Module x 2

Main Process Module x 8 + Sub Process Module x 2 + Load Lock Module x 2

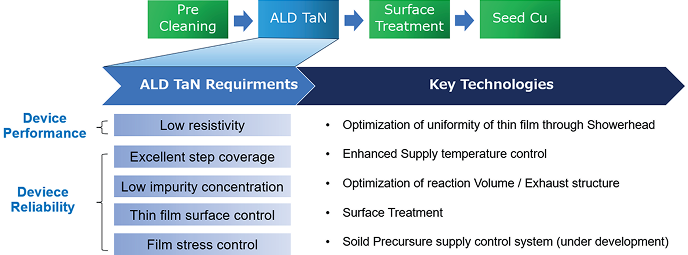

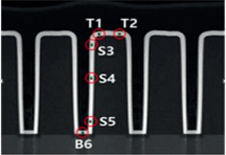

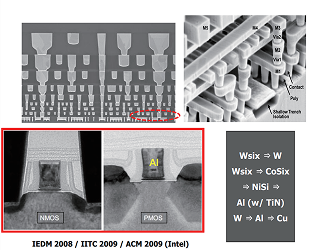

Cu Integraion Process Flow (In situ)

Excellent step coverage

in narrow patterns

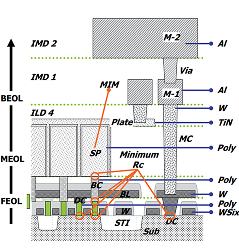

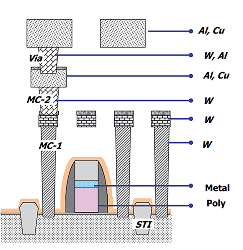

Logic Interconnect (Small,Fine Pitch)

ENTRON™-EX W300 Single System

ENTRON-EX W300 Tandem System

Cutting edge technology to Thin& thick films

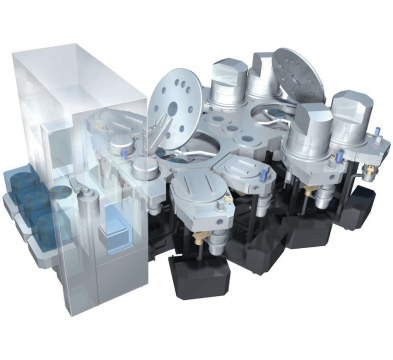

High Throughput and performance with multi

cluster chamber

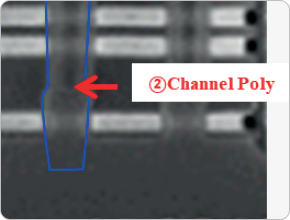

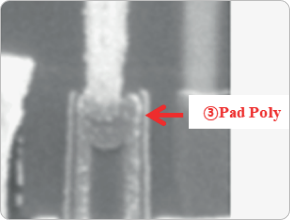

LOGIC

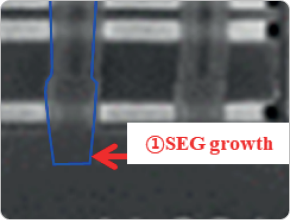

DRAM

NAND

Logic : Interconnection, DRAM & NAND : Gate Electrode, Interconnection, etc.

LOGIC

DRAM

NAND

WLP for Cu-RDL : RDL with Chip middle structure, Up to 8 stacked

HBM for Seed layer : Seed layer for micro bump pad to access TSV

2.5D Packaging, Hybrid Bonding, …

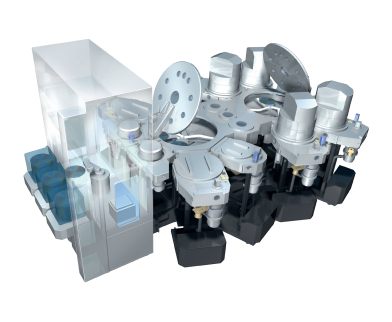

| SFEM /Core |

|

|---|---|

| Degas |

|

| Pre-Clean |

|

| Sputter |

|

GPU structure

CVD Module

PVD Module

Dry Clean Module

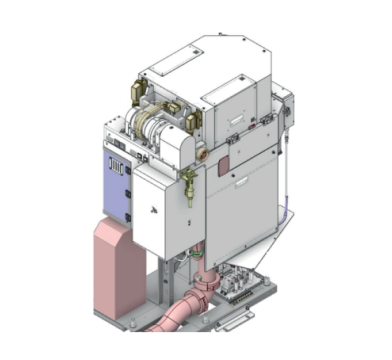

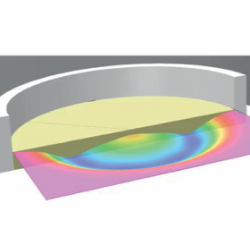

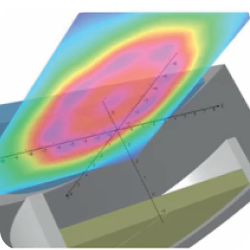

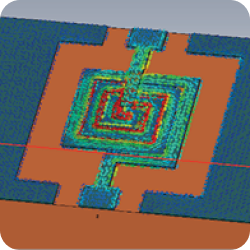

Target erosion profile

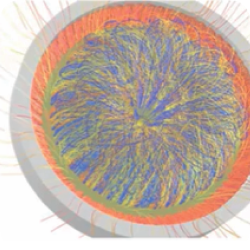

Plasma electron tracks

Deposition profile

on the substrate

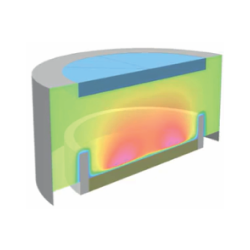

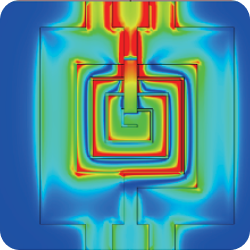

Voltage distribution

E-Field on plane

RF surface current

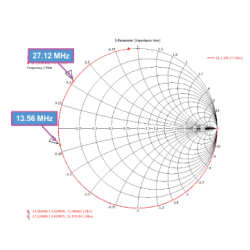

Smith chart(Matcher)

Voltage distribution